Mold Production Process

Yinghua International (HK) Ltd, in addition to the production of electronic components products, also focuses on Mold Products development, both in plastics and in metals.

Our process involves product development, mold making, injection molding processing. We work with patented and certified designs requirements, ensuring that the integrity of the process is maintained.

The mold process can be complex, but there are clear components of the process.

Mold casting is typically divided into types of material used. Whether metal, plastic, rubber, ceramic or powder, mold casting involves the initial step of material selection.

Subcategories of the casting process would include processing metal mold and processing powder metallurgical molds. Molds are generally single piece and small batch production.

Mold is a cast as a model, making the sample from which to make the larger quantities of products.

With the rapid development of macromolecule plastics, molds can be fine-tuned to more exacting specifications. Plastic molds can generally be divided into: injection molding, extrusion molding, gas-assisted molding and so on.

Plastic molds would include double color mold, mold and the extrusion die, etc.). Rubber molds and other developing materials are used, as well.

Plastic molds Categories: molding, injection molding, compression molding, extrusion molding, injection molding, blow molding, die casting molding

Hardware mold is divided into: Hardware mold is divided into:

Stamping die (such as blanking die, bending mold, deep drawing mold, double hole molds, shrinkage cavity mold, ups and downs, bulging mold, plastic mold, etc.)

Forging die (such as stamping die, upsetting forging die, etc.), extrusion mold, injection mold, die casting die, forging die, etc.

Non-metallic mold is divided into: the plastic mold and inorganic non-metallic mold.

According to the mold itself, different material, mold can be divided into: sand mold, metal mold, vacuum mold, wax mold and so on.

Molds, tool and die processes are used in conjunction to produce the machined parts necessary for proper production.

Here is a sample of the steps required to produce the desired product mold:

1) The initial stage is mainly between customer and Supplier for product design and mold development technology discussion. This colloboration will ensure that the product designers have a clear idea of what the end product is It is important that the supplier clearly grasp the product designer’s design intent and requirement, but also for product designers to better understand the ability of the mold production, the process performance of the product, so as to make a more exact design.

2) Pricing (Quotation) will be provided once the scope of the project is clearly understood. This would include the price of the mold, the mold life, flow process, machine tonnage as well as the mold delivery date.(quotation including product information such as size weight, mold size weight.)

3) Order (Purchase Order): customer orders, a deposit, and the Order accepted.

4) Mold Production plan and arrange Production Planning and Schedule Arrangement. This stage sets the date of the date of delivery to the customer's requirements.

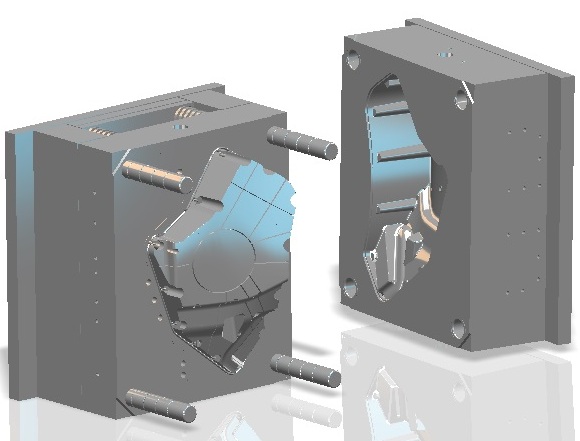

5) Mold Design As needed, available programming services are available in Design softwareuse, such as Pro/Engineer, UG, Solidworks, AutoCAD, CATIA, etc

6) Material purchasing is implemented.

7) Mold processing (Machining). This is a process involving milling, heat treatment, grinding, computer gongs (CNC), EDM (EDM), line (WEDM), coordinates, grinding (JIG GRINGING), laser engraving, polishing, etc.

8) Mold Assembly

9) Mold testing (Trial Run)

10) Sample evaluation report (SER): Customer provides feedback on test results.

11) Sample evaluation report Approval (SER Approval). Customer approves the testing as successful to allow further ordering of quantities desired.

The mold has an irreplaceable role in our life, most of our articles for daily use without mold, such as, computers, telephones, fax machines, keyboards, glass and so on these plastic products is needless to say, like a car and motorcycle engine cover is also with mold making, light a car all kinds of mold will be used more than 20000. So the role of the modern life of mold can not be replaced. As long as the mass production is inseparable from the mold.

|